Quality

AL.CA.FOND’s commitment is to ensure a high-quality product, capable of satisfying the needs of the most demanding customer. In our fully-equipped workshop, all the raw materials go through the strictest inspection checks before being accepted for melting.

Then, according to their characteristics and type, they are conveyed on to the various processes: drying, iron removal, crushing, etc. which will further improve their properties. The melting and refining stages are constantly monitored and the various tests that the metals undergo reveal a comprehensive overview of the technical and qualitative characteristics of the alloy present in the furnace.

When all the parameters combine to assign a metal to a particular type of alloy, the metal goes on to the ingot-casting and stacking stage. In 2000 AL.CA.FOND decided to adapt its quality management system so as to conform to the parameters required by DNV and obtained the relevant certification.

At present, AL.CA.FOND is also ISO 9001 certified.

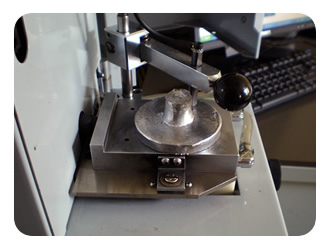

We are equipped with the following product-testing facilities:

- Inspection Check Lab;

- Analysis Lab;

- Quantometers;

- Durometers;

- Lapping devices;

- Residual Gas Analysers;

- Microscopes;

- Radiometric Analysers;